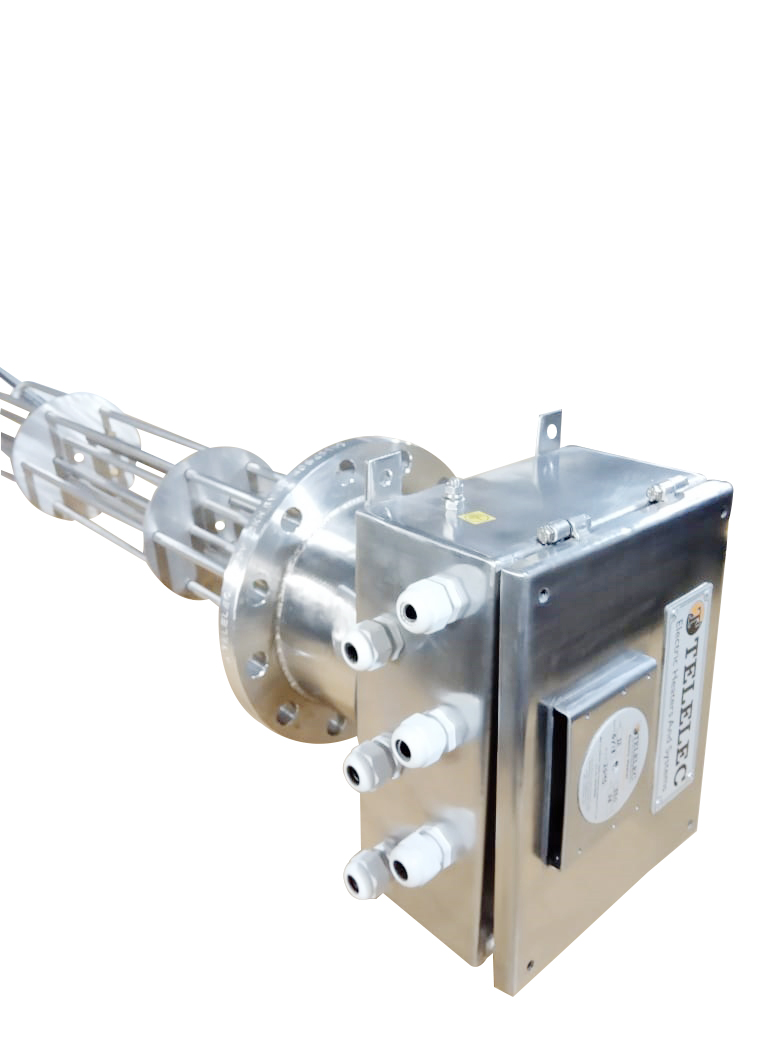

Overview

Owing to their basic design and construction, no special area has to be earmarked for electric heaters and they can be installed virtually anywhere in the plant. In classified hazardous area, heaters can be installed in zone 1 classified areas. Moreover, electric heaters are compact and being electrical equipment, no special interfaces or sensors are required to integrate them into the plant control or building management system.Sophisticated technologies, and in-built and simple to operate, programmable safety mechanisms and interlocks ensure smooth operation, even from long distances. The alternative to electric heating is of course fuel based systems that may run on fuels like natural gas, diesel, HFO etc. Though they may seem to cheaper at the outset, any decision on which energy source to use should be accompanied by the following considerations.

Reviews

There are no reviews yet.